|

Henan Hongji Mine Machinery Co., Ltd.

|

Paper Mill Lime Mud calcination machine

| Price: | 350000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

New design lime mud rotary kiln used in paper mill project for CaO recycle

Energy saving, easy to operate

Advanced techinical, enviroment friendly

Project back groud

We now cooperate with Panjapol Pulp Industry Company in Thailand for lime mud calcination project for their paper mill. They use eucalyptus as raw materials to produce various types of paper, White sludge concentration of 35%, the daily processing capacity is 185 tons, production of 130 tons per day. To take full advantage of local resources, Henan Hongji recommends kiln heating using eucalyptus bark and tail kiln heat recycling as a heat source, reduce fuel costs and improve productivity.

How it comes

Formation of Paper White Sludge

Paper white sludge is a solid waste generated in the pulp and paper companies recover alkali process. The main component of Paper White Sludge is CaCO3 which takes up 80-90% of the white sludge. For every ton of paper or pulp, it will contain an average of 0.8-1 tons of white mud. White sludge contains S2-, SO42-, SO32-, Na +, OH- plasma, but also contain impurities such as SiO2. Paper white sludge is rich in alkaline. Its PH value is between 9-12 of strong corrosive type.

While lime mud damage

Paper white sludge environmental impact

Due to the processing cost and technology limitations, there are only a few pulp and paper making companies recycling white sludge. Most of the companies opt for the choice of sites for landfill or stacking. This practice does not only waste a lot of limestone resources, it also allows white sludge impurities penetrate into the ground with rainfall, endangering surrounding soil and groundwater resources and causing serious secondary pollution. As public concern for environmental quality is increasing, intense land resources for landfill disposal is increasingly difficult. Meanwhile, the open-air stockpiles of white clay will form dust pollution which will impact air quality.

Solutions

The proposal uses the same amount of CaCO3 and CaO interchangeability exists to achieve recycling white sludge resources, namely: CaCO3 = CaO + CO2 CaO + H2O + CO2 = CaCO3 + H2O. White sludge recycling rate is up to 95% or more . At present, the method is mainly represented by the rotary lime kiln powered by heavy oil, natural gas, or coal gas as the fuel to achieve recycling white sludge resources. However, in this case with PPI, our proposal allows the usage of biomass or wet sludge from waste water as fuel. This method technology of lime klin is mature with guarantee of high ratio of recycling capacity, high recovery rate and high degree of automation.

Hongji Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (800-1350℃ calcination) in a continuous process. Materials produced using rotary kilns include:

Cement

Lime

Refractories

Metakaolin

Titanium dioxide

Alumina

Vermiculite

Iron ore pellets

They are also used for roasting a wide variety of sulfide ores prior to metal extraction.

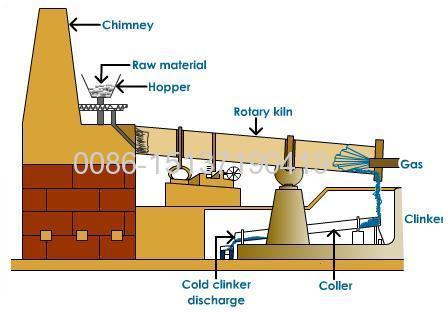

Working principle:

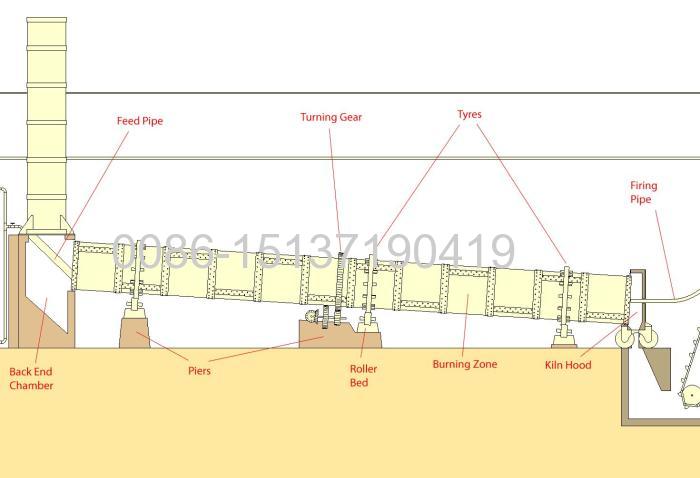

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil, pulverized petroleum coke or pulverized coal.

Structure

The basic components of a rotary kiln are the shell, the refractory lining, support tyres and rollers, drive gear and internal heat exchangers.

Machine packing and delivery

Machine woking

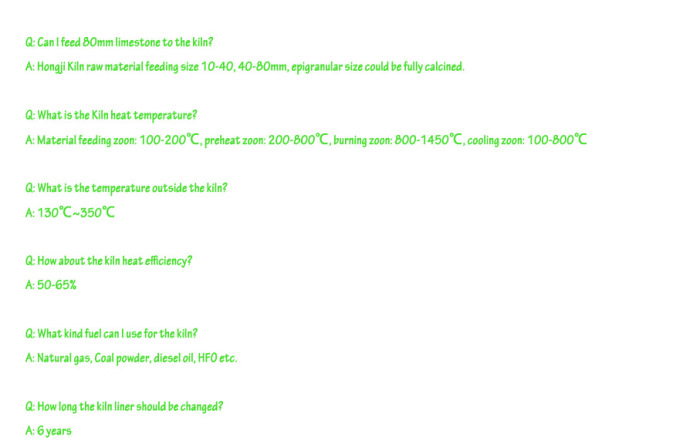

FRQ

About us

We

Henan Hongji Mine Machinery Co., Ltd. is a professional mining

machinery manufacture with ISO, CE Certificate, specialized in produce

and develop various kinds mining machines for over 40 years, we are

professional in:

- Stone crushing production line 5-500tph

- Sand making production line 50-200tph

- Ferro & Non ferro beneficiation process line (Au, Cu, Mo, Pb, Zn, Mn, Fe, Mn, etc)

- Industrial drying equipments (For sand, gypsum, filter cake, peat, biomass, clay, fertilizer, bentonite, Kaolin)

- Powder grinding equipments 80-200 mesh ( limestone, cement clinker etc)

- Cement/ Lime/ LECA production line with rotary kiln

Honors and Certificates

Service

Pre-sale:

1. Depending on customer's requirement, we insist on "making profit at lowest investment" and choose best machine.

2. Design the most reasonable project and maximum customers' profit.

3.Provide engineers to scene to plan work site.

4. Provide equipment list,design drawing, construction drawing, equipment install drawing.

During-sale:

1.Depend on scene, draw design drawing , construction drawing,

equipment install drawing. 2.Manufacturing products strictly on contract

while customer constructing.

3.Testing ex-work, delivery, customer acceptance.

After-sale:

1.Provide engineer to wok site guiding install.

2.Test equipment after installation, training operators.

3.Visit work site regularly

Please do not hesitate to contact with us for more details!

Skype: kellyliu_1987

M.P. 0086-15137190419