|

Henan Hongji Mine Machinery Co., Ltd.

|

Wet grinding mill usage

| Price: | 62000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

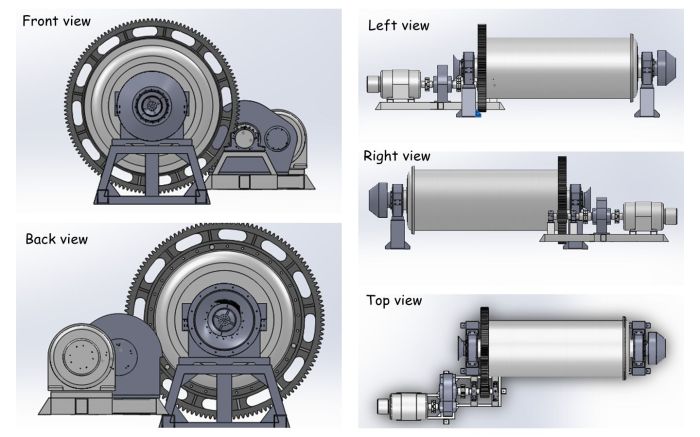

Ball grinding mill

Low cost in power, grinding meida, installation

Continue or batch accept

Applicable for materials of all degrees of hardness

The ball grinding mill is used for grinding materials such as coal, pigments, and felspar for pottery. Grinding can be carried out either wet or dry but the former is performed at low speed. Blending of explosives is an example of an application for rubber balls

Ball milling boasts several advantages over other systems: the cost of installation, power and grinding medium is low; it is suitable for both batch and continuous operation, similarly it is suitable for open as well as closed circuit grinding and is applicable for materials of all degrees of hardness.

A ball mill works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shell.

In case of continuously operated ball mill, the material to be ground is fed from the left through 60° cone and the product is discharged through a 30° cone to the right. As the shell rotates, the balls are lifted up on the rising side of the shell and then they cascade down (or drop down on to the feed), from near the top of the shell. In doing so, the solid particles in between the balls are ground and reduced in size by impact.

We Henan Hongji Mine Machinery Co., Ltd. is a professional mining machinery manufacture with ISO, CE Certificate, specialized in produce and develop various kinds mining machines for over 40 years, we are professional in:

- Stone crushing production line 5-500tph

- Sand making production line 50-200tph

- Ferro & Non ferro beneficiation process line (Au, Cu, Mo, Pb, Zn, Mn, Fe, Mn, etc)

- Industrial drying equipments (For sand, gypsum, filter cake, peat, biomass, clay, fertilizer, bentonite, Kaolin)

- Powder grinding equipments 80-200 mesh ( limestone, cement clinker etc)

- Cement/ Lime/ LECA production line with rotary kiln

Pre-sale:

1. Depending on customer's requirement, we insist on "making profit at lowest investment" and choose best machine.

2. Design the most reasonable project and maximum customers' profit.

3.Provide engineers to scene to plan work site.

4. Provide equipment list,design drawing, construction drawing, equipment install drawing.

During-sale:

1.Depend

on scene, draw design drawing , construction drawing, equipment install

drawing. 2.Manufacturing products strictly on contract while customer

constructing.

3.Testing ex-work, delivery, customer acceptance.

After-sale:

1.Provide engineer to wok site guiding install.

2.Test equipment after installation, training operators.

3.Visit work site regularly

Please do not hesitate to contact with us for more details!

Skype: kellyliu_1987

M.P. 0086-15137190419

.jpg)

.jpg)

.jpg)